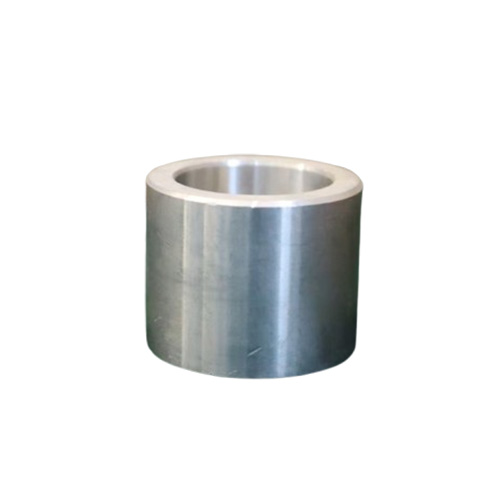

Socket equal diameter pipe clamp

Socket equal diameter pipe clamp is a type of pipe fitting used to connect two pipes of the same diameter, and has a wide range of applications in pipeline systems such as construction, municipal, chemical, and water conservancy. Here is a detailed introduction about it:

Structural characteristics

Shape: Typically cylindrical in shape, with open ends and an inner diameter equal to the outer diameter of the connected pipeline. Its length is generally short, with common specifications such as 50mm and 100mm. The specific length varies depending on different usage scenarios and pipeline diameters.

Connection method: Adopt socket connection, that is, one end of the pipe has a slightly larger inner diameter than the other end, forming a socket and a plug. When connecting, insert one end of the pipeline into the socket of the fitting, and then seal it with sealing materials such as rubber rings, sealant, etc. to confirm the sealing and stability of the connection.

Materials and Characteristics

Materials: Common materials for socket and equal diameter pipe clamps include cast iron, carbon steel, stainless steel, plastic, etc.

Characteristics: The cast iron material pipe clamp has the characteristics of good strength, good performance, and strong corrosion resistance (based on actual reports), and is suitable for some pipeline systems with high requirements for strength and corrosion resistance (based on actual reports), such as urban water supply and drainage pipelines. Carbon steel pipe clamps have high strength and relatively low cost, and are commonly used in general industrial pipelines and building water supply and drainage pipelines. Stainless steel pipe clamps have excellent corrosion resistance (based on actual reports) and hygiene performance, and are widely used in industries with high hygiene requirements such as food, beverage, and pharmaceuticals. Plastic pipe clamps such as PVC, PPR, etc. have the advantages of light weight, corrosion resistance (based on actual reports), easy installation, and reasonable price. They are widely used in the water supply and drainage systems of civil buildings and some chemical pipelines.

Application industry

Water supply and drainage system: In urban water supply and drainage pipelines and internal building water supply and drainage pipeline systems, socket and equal diameter pipe clamps are used to connect pipes of the same diameter, achieving water transportation and distribution. For example, in the laying of outdoor water supply and drainage pipelines in residential areas, pipes are connected one by one through socket and equal diameter pipe clamps to form a complete water supply and drainage network.

Gas pipeline system: In gas transmission pipeline systems, socket and equal diameter pipe clamps are also used. However, for the pipe clamps used in gas pipelines, their sealing performance and safety requirements are high, and special sealing materials and connection processes are usually used to confirm that the gas will not leak.

Chemical pipeline system: In chemical production, many pipelines need to transport various corrosive liquids or gases. Suitable corrosion-resistant materials (based on actual reports) should be selected for the socket and equal diameter pipe clamps, which can meet the connection requirements of chemical pipelines and protect the safe and stable operation of the pipeline system.

Installation and usage precautions

Pipeline cleaning: Before installing the socket and equal diameter pipe clamp, it is necessary to clean the connection end of the pipeline, remove surface impurities such as oil, dust, rust, etc., to confirm a tight connection.

Sealing material installation: Install the sealing material correctly, such as placing the rubber ring in the designated position of the socket, and confirm that it is flat and free of distortion. When using sealant, it should be evenly applied to the connecting surface to avoid missing or uneven application.

Insertion Scale: When inserting the pipeline into the pipe clamp socket, it is necessary to confirm that the insertion scale meets the requirements. Generally, it should reach the designated scale mark of the pipe fitting socket to protect the firmness and sealing of the connection.

Installation environment: Avoid installing in harsh environmental conditions, such as high temperature, humidity, and strong sandstorms, to avoid affecting the sealing effect and the service life of pipe fittings. At the same time, during installation, attention should be paid to avoiding external impact or compression on the pipe clamp to prevent deformation or damage.

Flange Facing Types and Their Role in Leak Prevention

Explore common flange facing types and how they prevent leakage in piping systems, with a focus on Weld Neck Flange manufacturing, production quality, and factory bulk supply control.

2026-01-24

Export-Ready Packaging Solutions for 304 PN6 Flanges

Learn how export-ready packaging protects 304 PN6 Plate Welding Flange products during global shipping, supported by manufacturer production and factory-level bulk supply systems.

2026-01-23

Applications of Stainless Steel Elbows in Marine and Offshore Engineering

Discover how Stainless Steel Elbow components support marine and offshore engineering with corrosion resistance, strength, and reliability backed by manufacturer production and factory-level supply.

2026-01-22

Understanding ISO Testing Standards for 20592PL Flanges

Explore ISO testing standards for 20592PL flanges and learn how Plate Welding Flange quality is ensured through manufacturer-level production and factory inspection for safe industrial piping systems.

2026-01-21