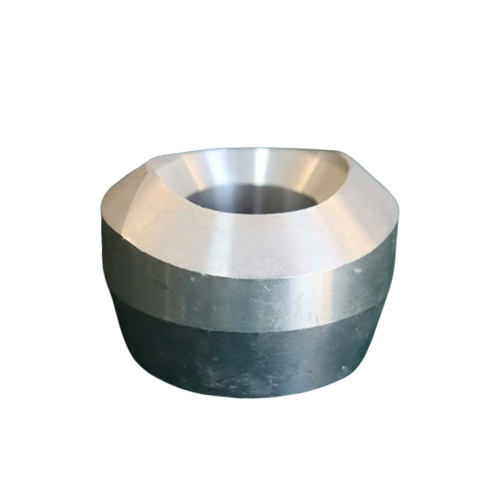

Arc shaped socket and branch pipe seat

Socket branch socket arc-shaped is a type of pipe fitting used for pipeline connection, belonging to a type of branch socket. Here is an introduction about it:

Structural characteristics

Overall shape: usually curved, designed to better fit the outer surface of the main pipe, with a smoother and smoother connection to the main pipe, reducing resistance and turbulence when fluid flows inside the pipeline.

Connection method: One end of the curved socket of the plug-in branch pipe seat is a socket for inserting the branch pipe, and the other end is connected to the main pipe through welding or other connection methods. This connection method can provide excellent sealing performance and confirm the safe operation of the pipeline system.

Materials and Characteristics

Material: Generally made of materials that are the same or compatible with the pipeline, such as carbon steel, alloy steel, stainless steel, etc.

Characteristics: It has good strength and toughness, and can withstand the pressure and impact force of the fluid inside the pipeline. At the same time, according to different materials, they also have corresponding characteristics such as corrosion resistance (based on actual reports) and high temperature resistance (based on actual reports) to adapt to various working environments. For example, the curved socket of stainless steel material is suitable for industries such as chemical and food industries that require high corrosion resistance (based on actual reports); Carbon steel materials can be used for general industrial pipeline systems.

Application industry

Industrial pipeline system: In the pipeline systems of industries such as petroleum, chemical, power, metallurgy, etc., it is commonly used to connect branch pipes and main pipes to achieve functions such as fluid diversion and convergence. For example, in the pipeline system of a petroleum refinery, the arc-shaped socket and branch pipe seat can be used to connect pipelines between different process equipment, allowing fluids such as crude oil and finished oil to flow smoothly between various equipment.

Building water supply and drainage system: It is also applied in the internal water supply and drainage pipeline system of buildings, used to connect the branch pipes and main pipes of sanitary appliances, water equipment, etc. For example, in residential bathrooms, the curved socket of the branch pipe seat can connect the drainage branch pipes of toilets, washbasins, and other sanitary appliances with the main drainage pipe to ensure smooth drainage.

Installation and usage precautions

Pre installation inspection: Before installation, it is necessary to check whether the specifications and dimensions of the socket branch pipe seat arc match the main and branch pipes, and whether there are defects, cracks, and other issues on the surface of the pipe fittings. At the same time, it is necessary to confirm that the connection between the main and branch pipes is clean and free of impurities to protect the quality of the connection.

Welding requirements: If welding connection is used, it is necessary to strictly follow the welding process specifications to confirm the quality and strength of the weld seam. Welding personnel should have corresponding qualifications and experience. After welding is completed, non-destructive testing such as radiographic testing, ultrasonic testing, etc. should be carried out on the weld seam to check for internal defects.

Insertion Scale: When inserting the branch pipe into the arc-shaped socket of the socket, the insertion scale should be protected to meet the specified requirements to confirm the sealing and firmness of the connection. Generally speaking, the insertion scale should be determined based on the specifications and design requirements of the pipe fittings, and can be controlled by marking on the branch pipes or other methods.

Usage and maintenance: During use, regular inspections of the pipeline system should be carried out, including checking for leaks, looseness, and other issues at the curved connection parts of the socket and branch pipe seats. If problems are found, they should be dealt with in a timely manner to avoid accidents. At the same time, attention should be paid to anti-corrosion (based on actual reports), insulation and other maintenance measures for the pipeline system to extend the service life of pipelines and fittings.

Flange Facing Types and Their Role in Leak Prevention

Explore common flange facing types and how they prevent leakage in piping systems, with a focus on Weld Neck Flange manufacturing, production quality, and factory bulk supply control.

2026-01-24

Export-Ready Packaging Solutions for 304 PN6 Flanges

Learn how export-ready packaging protects 304 PN6 Plate Welding Flange products during global shipping, supported by manufacturer production and factory-level bulk supply systems.

2026-01-23

Applications of Stainless Steel Elbows in Marine and Offshore Engineering

Discover how Stainless Steel Elbow components support marine and offshore engineering with corrosion resistance, strength, and reliability backed by manufacturer production and factory-level supply.

2026-01-22

Understanding ISO Testing Standards for 20592PL Flanges

Explore ISO testing standards for 20592PL flanges and learn how Plate Welding Flange quality is ensured through manufacturer-level production and factory inspection for safe industrial piping systems.

2026-01-21